Building a resilient Supply Chain with AI: Lessons from Sigmoid, PepsiCo, and ISG

Reading Time: 5 minutes

Gartner projects that by 2028, 25% of supply‑chain KPI reporting will be powered by Generative AI.1 This shift signals a broader transformation where AI is actively shaping decisions across the supply chain.

In a recent webinar, Sigmoid, PepsiCo, and ISG discussed how companies are using AI and advanced analytics to improve forecast accuracy, reduce operational friction, and build a more agile, responsive supply chain.

4 trends reshaping global supply chains

Global supply chains are evolving faster, driven by disruption, digitalization, and rising customer expectations. The following four shifts are grounded truths shaped by experience, data, and execution by those solving real-world supply chain challenges every day.

- VUCA is the baseline: Volatility, uncertainty, complexity, and ambiguity have become constants in global supply chains, driven by geopolitical shifts, trade conflicts, and unexpected disruptions that demand faster, smarter responses.

- Zero tolerance for delays: Speed, transparency, and sustainability are now non-negotiable. AI is critical for enabling accurate forecasting, real-time visibility, and resilient operations.

- Generative and Agentic AI: These technologies are driving real improvements in forecasting, scenario planning, and autonomous decision-making across the supply chain.

- Strategy must meet execution: Success depends on more than vision. Companies are turning to partners who combine deep domain knowledge with AI expertise to make transformation happen on the ground.

How PepsiCo and Sigmoid are building resilient supply chains with advanced analytics.

Priorities to build resilience and agility

As supply chains evolve from reactive networks to proactive ecosystems, enterprises are investing in specific capabilities that offer both resilience and agility. Four areas, in particular, have emerged as strategic priorities for companies looking to future-proof their operations.

- Control Towers for real-time visibility: Modern control towers go beyond monitoring, they offer real-time simulation, scenario planning, and impact analysis. By aggregating data from across the supply chain, these systems help leaders test decisions before executing them, enabling faster, more informed actions during disruption.

- Risk-aware operations: AI is changing the way companies manage risk. By mapping geopolitical volatility, supplier dependencies, and macroeconomic indicators, businesses are building smarter models to assess trade-offs and stay ahead of disruptions, whether from war, regulation, or raw material shortages.

- Autonomous, cross-functional decision-making: Gone are the days of siloed planning. AI is now stitching together inputs across supply chain, finance, procurement, and commercial functions to drive coordinated, real-time decision-making. From inventory optimization to automated order placement, operations are becoming faster and more responsive.

- Circular and sustainable supply chains: Sustainability today has to be baked into core workflows and can no longer be a standalone initiative. AI helps in forecasting emissions, reducing waste, and track product lifecycles, supporting circular supply chains that are both efficient and responsible.

But progress isn’t uniform. Many organizations still struggle with disconnected systems, inconsistent data, and resistance to change. To move from pilots to scale, enterprises must address these foundational barriers head-on.

Enabling intelligent supply chains in the age of GenAI and Agentic AI

Generative AI and Agentic AI are redefining how modern supply chains operate. From decision support to exception handling and planning automation, these technologies are becoming essential tools in driving agility, responsiveness, and intelligence. Companies leveraging GenAI for scenario simulation and forecasting are already reporting improvements in forecast accuracy by 15–35%2. Acting as a co-pilot, GenAI helps planners make faster and more confident decisions by providing contextual insights in real time.

What makes these technologies especially transformative is their versatility and usability. GenAI can simulate multiple dynamic scenarios, generate actionable recommendations, and offer intuitive, conversational interfaces that reduce user friction.

Agentic AI takes this a step further by evolving from passive assistants to intelligent decision-making agents. These systems anticipate, recommend, and act, helping enterprises shift from reactive to proactive supply chain strategies.

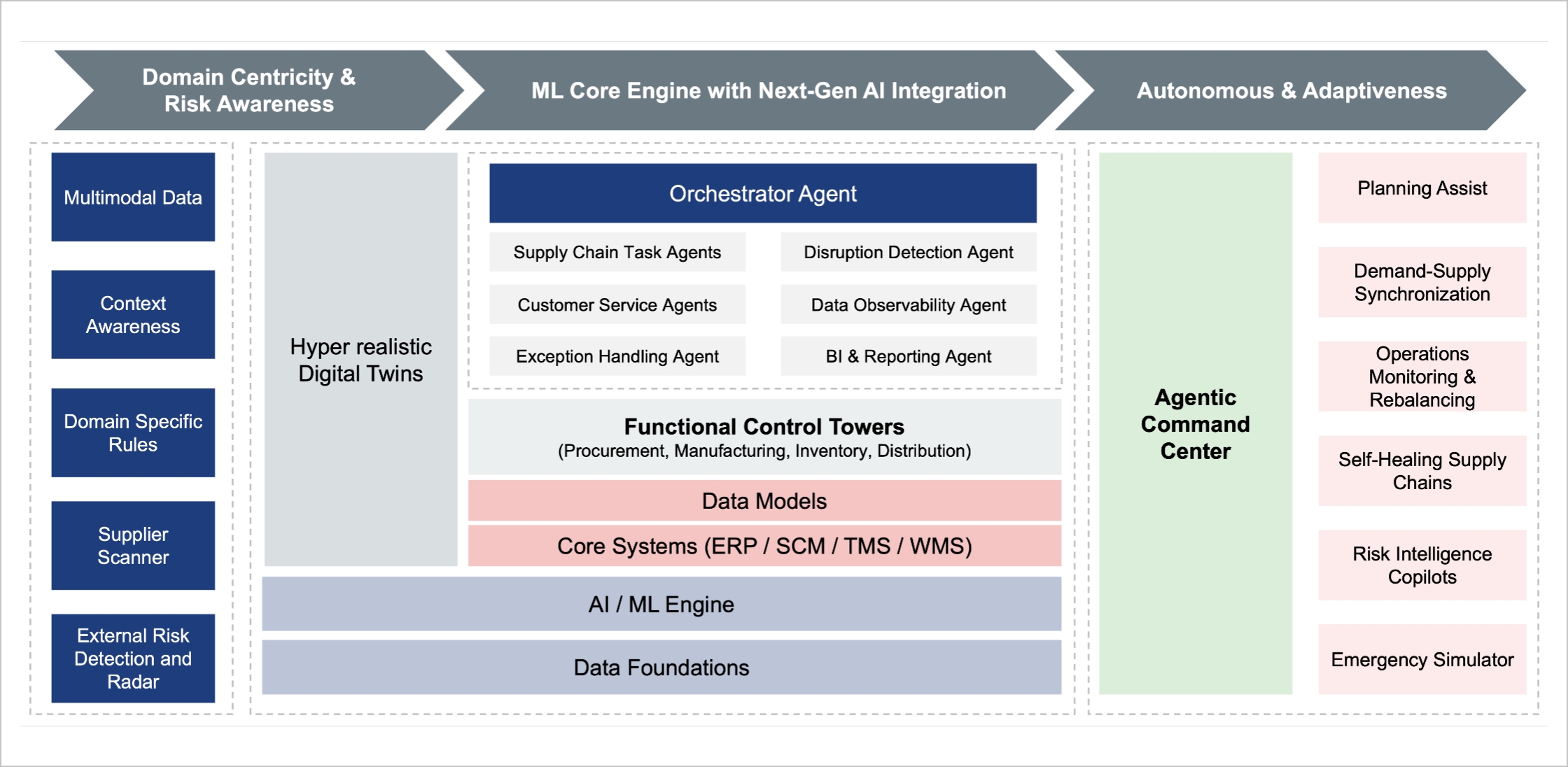

Architecture to get started with Agentic AI

To support this new era of intelligent operations, enterprises must invest in a modern AI-native architecture purpose-built for Agentic AI and GenAI.

Inside the PepsiCo-Sigmoid collaboration

PepsiCo partnered with Sigmoid to improve the accuracy and consistency of its demand forecasting process across global markets. With planning approaches varying across teams and regions, the goal was to build a unified forecasting system that would enable better alignment between supply chain, commercial, and finance functions.

At the heart of this effort is a custom-built platform called FAST, designed to generate accurate demand forecasts, support scenario planning, and streamline decision-making around concentrate purchases and inventory targets.

One of the key issues PepsiCo faced was the different planning approaches across regions and functions, which often led to misalignment and inefficiencies. The new solution standardizes forecasting processes, allowing teams to simulate different demand scenarios, align on purchasing plans, and make timely, data-driven decisions. Its intuitive interface and simulation capabilities have enabled PepsiCo to plan ahead with more confidence.

The platform has helped PepsiCo enhance short-term forecast accuracy, reduce operational waste, and drive more coordinated planning cycles. The collaboration with Sigmoid continues as the platform evolves to support broader use cases and deeper integration across the business.

Conclusion

Resilient supply chains can’t be built with siloed systems and generic AI. They’re shaped by intelligence that understands context and acts in real time. Enterprises need AI agents trained on domain-specific data, integrated with live signals, and built to drive decisions. The edge will belong to those who turn complexity into clarity and speed into strategy.

To hear directly from the leaders shaping these strategies, watch the on-demand webinar with Sigmoid, PepsiCo, and ISG.

Featured blogs

Subscribe to get latest insights

Talk to our experts

Get the best ROI with Sigmoid’s services in data engineering and AI

Featured blogs

Subscribe to get latest insights

Featured blogs

Talk to our experts

Get the best ROI with Sigmoid’s services in data engineering and AI