Supply Chain Analytics

Optimize your supply chain process with data and AIHome / Who we serve / By Function - Supply Chain

Streamline supply chain operations with real-time data analytics services

Macroeconomic uncertainties, geopolitical strains, and market disruptions have strained global supply chains. As a result, companies are turning to intelligent supply chain operations equipped with predictive maintenance, real-time demand forecasting and route optimization. Sigmoid offers a comprehensive portfolio of end-to-end supply chain data management and AI/ML analytics services that unify siloed data sources, build connected supply chains, and scale real-time analytics across the enterprise. Our industry-specific accelerators, powered by supply chain generative AI enhance predictive analytics to drive smarter, more proactive decisions. With a collaborative, consulting-led approach, we customize management analytics to enable data-driven decision-making at every stage of the supply chain — from procurement and logistics to inventory management.

How PepsiCo and Sigmoid are building resilient supply chains with advanced analytics

Hear from industry leaders of PepsiCo, ISG, and Sigmoid on how AI and advanced analytics are transforming supply chain planning. Gain practical insights into building resilient supply chains, and explore key trends like VUCA, Zero Tolerance, and Agentic AI that are reshaping traditional supply chain models to drive faster decision.

Watch nowCreating a transparent and resilient supply chain with analytics

Predictive supply chain analytics plays a critical role in helping companies minimize supply chain risks, help create granular visibility and improve inventory management. Learn more about how companies are leveraging analytics to drive sales and optimize operations.

Read blog

Data driven insights at every stage of supply chain operations

Operations management & monitoring

Leverage internal, market research data and advanced ML models that preempt market dynamics and seamlessly predict future demand at category and brand levels with high accuracy.

Real-time data analytics for end-to-end visibility across the entire supply chain network. This enhanced visibility enables proactive identification of potential disruptions, allowing for faster decision-making and risk mitigation.

Track critical metrics like on-time delivery, quality, lead times, and responsiveness to identify top performers, negotiate better terms, and mitigate supply chain risks.

Production planning & warehousing

Leverage sensor data analysis and ML-driven anomaly detection to prevent costly unplanned machine downtime and optimize maintenance schedules.

Utilize historical data, demand forecasts, and ML simulations to identify and optimize resource allocation to meet future needs and avoid potential bottlenecks.

Enhance inventory planning with ML to continuously evaluating and optimize reorder points and order quantities to consistently minimize carrying costs while ensuring that products are always in stock.

Fulfillment & logistics management

Lower fulfillment costs, improve delivery speed, and enhance the customer experience by leveraging real-time order, location, and inventory data to optimize order-picking processes and shipping strategies.

Preempt potential stockouts with ML and guide proactive replenishment strategies, ensuring products are available on the shelves when and where customers want them.

Improve carrier selection, and shipment tracking using historical and real-time data to reduce costs and maximize delivery efficiency across the supply chain.

Network and distribution management

Reduce delivery times, and enhance overall operational efficiency with data driven route planning by analyzing data on vehicle location, speed, and fuel consumption in real-time with IoT sensors.

Leverage GPS tracking, driver data, and vehicle diagnostics to optimize route planning and monitor driver performance for improved vehicle maintenance, and enhanced delivery efficiency.

Determine optimal replenishment quantities and distribution strategies by analyzing data from demand forecasts, inventory levels, and lead times to ensure product availability while minimizing stockouts.

Why industry analysts recognize Sigmoid as a supply chain analytics leader

"Sigmoid’s investments in predictive and prescriptive analytics reflect its commitment to modernizing the data ecosystem and enhancing supply chain resilience. Through its portfolio of services, pre-built accelerators, and consultative approach, Sigmoid helps enterprises build connected supply chains and generate actionable insights for efficient planning and operations."

Manav Deep Sachdeva

Principal Analyst, ISG

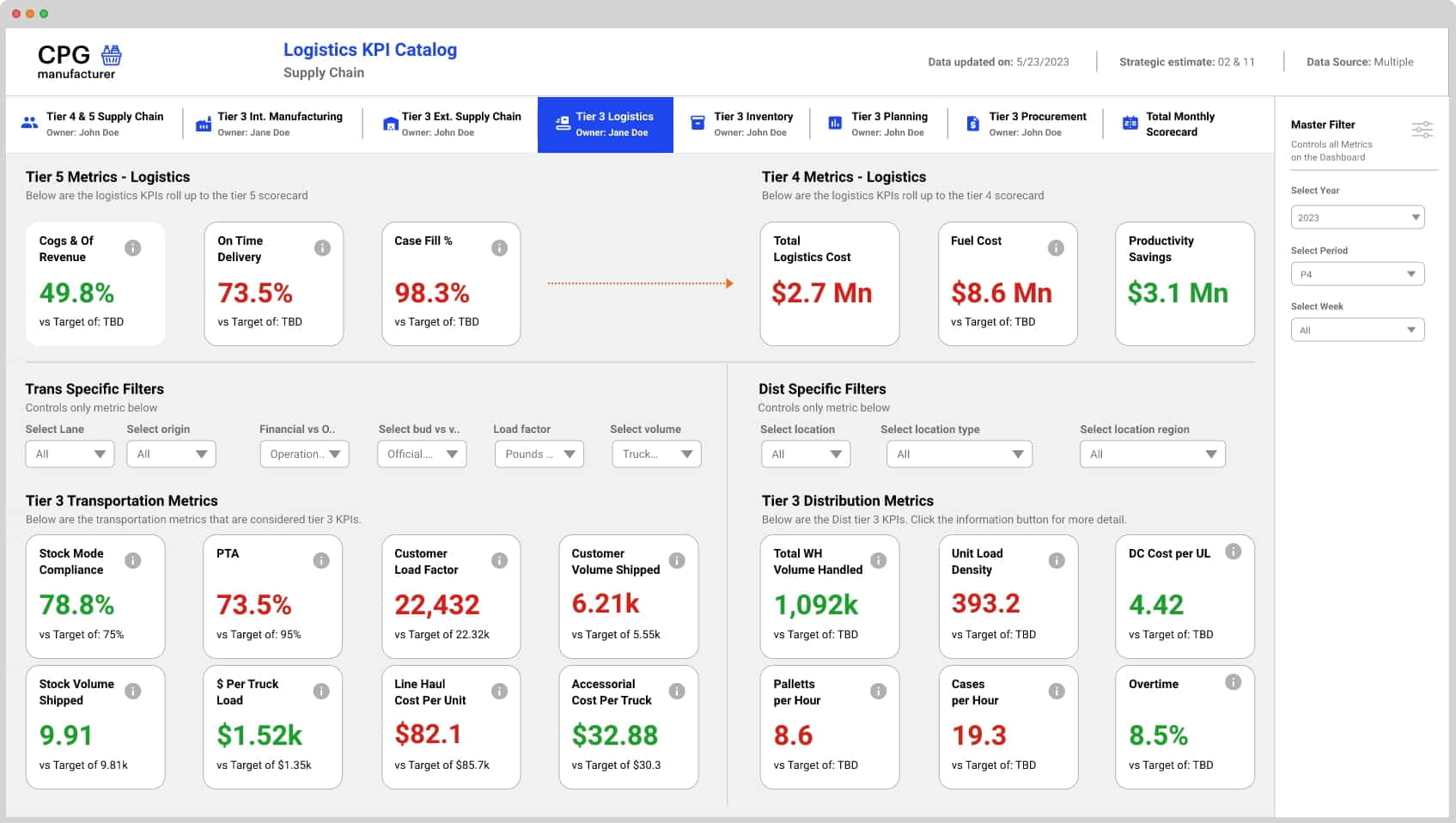

Integrated KPIs dashboard for enhanced supply chain performance monitoring

Inadequate visibility into supply chain processes hampers the ability to anticipate demand fluctuations, address procurement bottlenecks, and optimize cost efficiencies. Sigmoid's supply chain data analytics solutions can equip businesses with a Supply Chain Control Tower- harnessing high-quality data, supply chain teams can gain real-time visibility into key performance indicators via intuitive dashboards across all facets of the supply chain.

Customer success stories

$30 MN+ savings in inventory handling cost with effective demand forecasting for leading cosmetics company

- 70% better accuracy for demand forecasting

- $30 MN+ savings in inventory handling costs

- Increased overall product coverage to 92%

15% increase in capacity utilization with automated Master Production Schedule for a Fortune 500 biopharma manufacturer

- Near real-time visibility into operational metrics and KPIs

- 15% increase in capacity utilization

- 98% reduction in time for schedule generation

Customer testimonials

Sigmoid has developed an AI tool which is dynamic in a way that will look at the data and allow us to predict what the best solution is, depending on trends within the market. These tools that we've implemented in Germany have been hugely successful and will likely be deployed in other regions across our supply chain network.

Vasco Lemos

Head of Global Logistics,

Imperial Brands

Working with Sigmoid team has been instrumental in advancing the digitalization of our supply planning processes. Together, we've developed robust solutions for material purchasing planning and built dashboards that provide better visibility into key supply chain KPIs. Sigmoid has demonstrated strong technical expertise, agility, and a true partnership mindset throughout the project. The outcomes are driving greater efficiency, transparency, and enabling faster, data-driven decision-making across our operations in Latin America.

Douglas Ishikawa

Supply Chain Director,

PepsiCo

Sigmoid’s data science and data engineering teams are exceptional in understanding data and provide custom innovative solutions that directly impact the business revenue.

Michael Christian R. Collemiche

Head of Data and Analytics,

Belcorp

Sigmoid has been instrumental in transforming our logistics operations by providing actionable insights into our distribution network. Their expertise and deep understanding of our data have enabled us to identify key areas for improvement, streamline transportation routes, and enhance delivery reliability. With their data-driven approach, we’re better positioned to optimize costs and improve service across the UK market and beyond.

Bruno Esmeraldo

Consumer Self-Care International Logistics Director,

Perrigo

Sigmoid’s investments in predictive and prescriptive analytics reflect its commitment to modernizing the data ecosystem and enhancing supply chain resilience. Through its portfolio of services, pre-built accelerators, and consultative approach, Sigmoid helps enterprises build connected supply chains and generate actionable insights for efficient planning and operations.

Manav Deep Sachdeva Principal Analyst ISGThe Sigmoid team has consistently demonstrated exceptional performance across all evaluated areas. Communication has been clear, proactive, and professional, ensuring seamless collaboration throughout the project. The quality of deliverables often exceeded expectations, reflecting a deep understanding of requirements and technical excellence. Timeline management has been exemplary, with all milestones achieved within or ahead of schedule. Overall, the value delivered by the team is outstanding, reinforcing Sigmoid as a reliable and high-performing partner.